Exploring Metal Castings and their diverse uses across multiple industries

Checking out the Flexibility and Applications of Metal Casting in Modern Industry

Metal Casting are important to various industries, showing their flexibility in applications ranging from auto elements to aerospace design. Different casting procedures enable for the creation of sturdy parts and intricate styles. As sectors evolve, innovations and lasting methods are improving the landscape of Metal Casting. This improvement increases important concerns about the future duty of Metal Casting in production and style performance. What developments might redefine industry standards?

Introduction of Steel Casting Processes

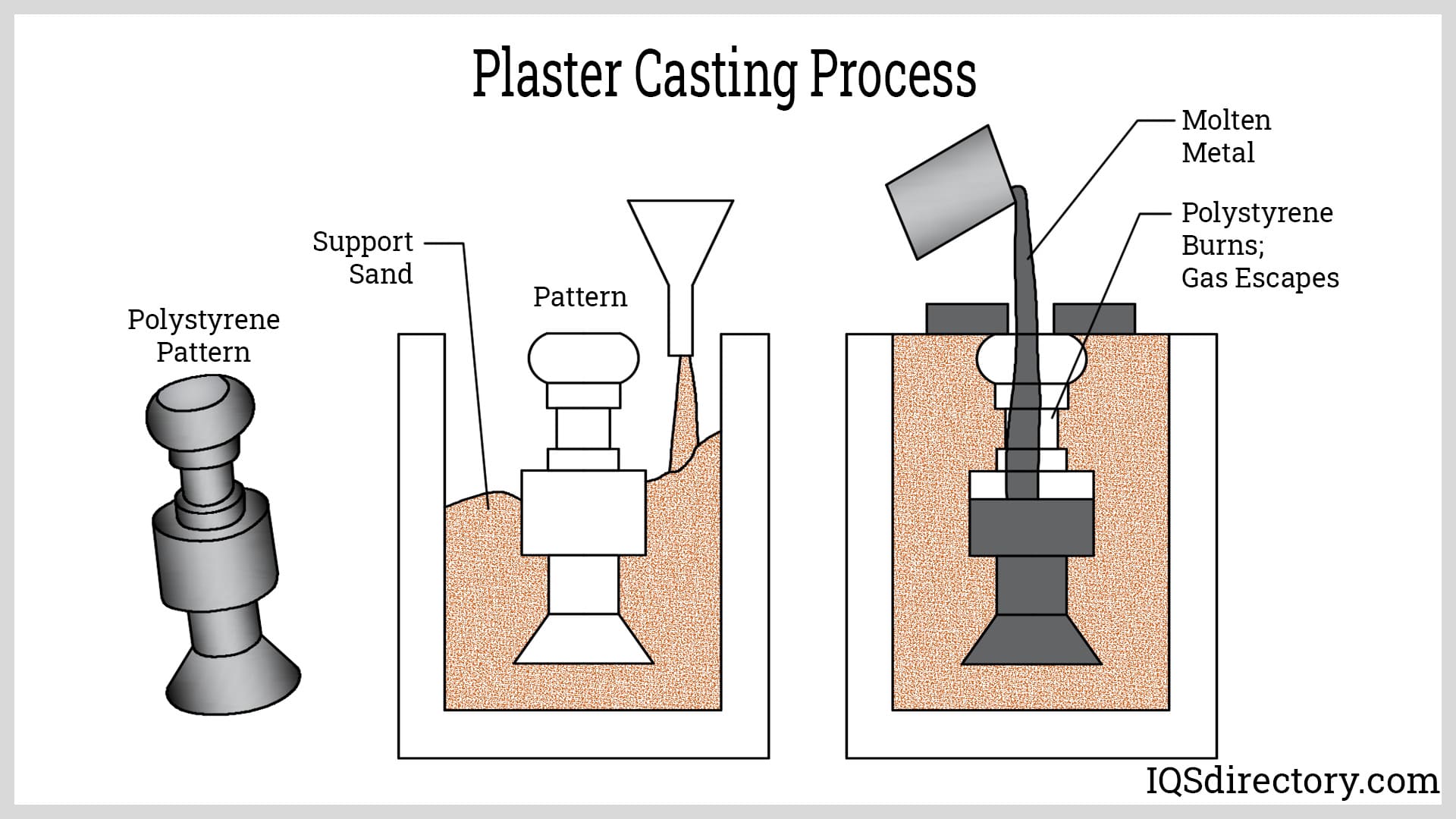

Although Metal Casting has actually evolved considerably over the years, its essential processes stay essential in modern production. Metal Casting involves numerous vital approaches, consisting of sand spreading, financial investment spreading, and die casting, each customized to certain applications and products. Sand casting, one of the oldest strategies, makes use of sand mold and mildews to form molten steel, making it perfect for huge parts. Financial investment spreading, recognized for its accuracy, uses wax patterns covered with ceramic to attain intricate designs, typically used in aerospace and clinical sectors. Pass away spreading, identified by high pressure, enables the rapid manufacturing of intricate forms with outstanding surface area coatings, typically made use of for automobile components. Each process supplies distinct advantages concerning price, intricacy, and product compatibility, enabling suppliers to pick the most suitable method for their requirements. As a result, comprehending these processes is necessary for enhancing production performance and achieving desired item specs in an open market.

Key Industries Using Metal Casting

Metal Casting play a crucial function in numerous key sectors, driving innovation and performance. The vehicle market is just one of the largest customers of Metal Casting, using them for engine parts, transmission housings, and architectural components. In aerospace, precision spreadings are critical for aircraft engines and architectural elements, guaranteeing safety and performance. The energy market additionally heavily relies upon Metal Casting for turbine components in power generation, as well as for oil and gas applications where resilience is extremely important. Additionally, the construction sector employs Metal Casting for structural frameworks, installations, and ornamental elements. Production devices and machinery take advantage of spreadings, which supply durable and reliable parts essential for operation. Ultimately, the medical field makes use of specialized castings for surgical instruments and implants, showcasing the flexibility of Metal Casting throughout diverse applications. Each of these markets demonstrates the importance of Metal Casting in advancing innovation and meeting particular functional demands.

Benefits of Metal Casting in Manufacturing

The advantages of Metal Casting in production are countless, adding substantially to the performance and performance of manufacturing procedures throughout different markets. One considerable benefit is the capacity to produce complex forms that would be challenging or impossible to attain with other manufacturing techniques. This complexity permits greater layout adaptability, allowing designers to enhance components for efficiency and capability.

Furthermore, Metal Casting can create top quality get rid of outstanding surface area finishes and dimensional precision, lowering the demand for comprehensive post-processing. Aluminum Castings. The procedure is also extremely scalable, suiting both big and small production runs without substantial adjustments in tooling or setup

Additionally, Metal Casting typically cause much less material waste compared to standard machining approaches, advertising more lasting production techniques. Overall, the convenience and efficiency of Metal Casting make them a preferred choice in industries such as vehicle, aerospace, and building, boosting performance and decreasing costs.

Developments in Metal Casting Technologies

As improvements in innovation continue to reshape the manufacturing landscape, advancements in Metal Casting are emerging to enhance sustainability, precision, and performance. Current developments consist of the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, which enable elaborate styles and reduced production times. Additionally, 3D printing technology has revolutionized mold-making, making it possible for fast prototyping and personalization without the demand for standard tooling.

Furthermore, the use of smart products and advanced alloys is expanding the efficiency capabilities of actors products, causing lighter and more powerful components. Automation and robotics are likewise playing a considerable role, improving processes and decreasing human error in production settings. These advancements not only boost the top quality of Metal Casting yet additionally add to cost-effectiveness with minimized waste and much shorter preparations. As the market advances, these technological innovations assure to redefine the future of Metal Casting.

Lasting Practices in Metal Casting

Sustainable practices in Metal Casting are getting importance as producers seek to minimize their environmental impact while preserving performance. Key techniques consist of the use of recycled materials, which substantially reduce basic material consumption and energy use. By including scrap metal right into the spreading process, business can decrease their carbon impact and promote resource effectiveness.

In addition, developments in energy-efficient innovations, such as electrical heaters and boosted insulation, are being adopted to optimize power use during production. Moreover, producers are significantly implementing water conservation methods to reduce waste and guarantee sustainable water monitoring methods.

The fostering of environmentally friendly casting materials, such as eco-friendly binders, is on the increase, changing standard compounds that might launch damaging discharges. Overall, the dedication to sustainability in Metal Casting not only addresses eco-friendly problems however also improves the market's competitiveness and lasting practicality in a quickly progressing market.

Case Researches: Success Stories of Metal Castings

The influence of Metal Casting can be seen across various markets, highlighting their versatility and efficiency. In the auto field, ingenious spreading methods have actually caused lighter and more fuel-efficient lorries, while aerospace advancements have led to innovative components that boost efficiency and security. In addition, the clinical area has actually taken advantage of precision spreadings that enhance tool functionality and individual end results.

Automotive Market Innovations

Development in the vehicle sector has been especially boosted by click over here now advancements in Metal Casting methods, which have permitted makers to produce lighter, extra sturdy parts. As an example, a leading vehicle company executed high-pressure die casting to develop engine blocks that are not only lighter yet also exhibit premium thermal efficiency. This shift considerably boosted fuel economic situation in their latest lorry designs. An additional case research study highlights the usage of sand spreading for generating detailed transmission parts, causing boosted efficiency and dependability. In addition, the intro of 3D printing in Metal Casting procedures has allowed the production of intricate geometries, promoting layout adaptability and reducing waste. Jointly, these technologies display just how Metal Casting are reshaping the vehicle landscape, driving improvements in efficiency and sustainability.

Aerospace Component Dope

Innovations in Metal Casting have also made considerable strides in the aerospace industry, where the demand for high-strength and light-weight components is crucial. Firms have successfully used sophisticated casting methods to create components such as generator blades and structural frameworks. A leading aerospace supplier executed financial investment casting to develop complicated forms that enhance performance while minimizing weight. This technique not only decreased production expenses yet also improved the resilience of the elements. One more remarkable situation included the usage of 3D printing combined with Metal Casting, allowing fast prototyping and faster turn-around times for brand-new designs. These success stories show the transformative effect of Metal Casting innovations, promoting technology and performance in aerospace manufacturing.

Medical Device Applications

Metal Casting have actually emerged as a pivotal technology in the advancement of medical gadgets, giving options that improve both functionality and client security. Situation researches highlight the effective combination of Metal Casting in numerous applications. Orthopedic implants made via precision spreading techniques offer enhanced stamina and biocompatibility, greatly enhancing client results. In one more instance, custom-made medical tools are created making use of Metal Casting, permitting customized solutions that satisfy certain step-by-step requirements. Additionally, the use of light-weight steel alloys in analysis equipment has actually brought about enhanced portability and ease of usage in scientific settings. These success stories highlight the essential duty of Metal Casting in progressing clinical technology, making certain devices are not just efficient however also risk-free for individual treatment.

Future Trends in Metal Casting Applications

The future of Metal Casting applications is positioned for substantial change through the combination of additive manufacturing and wise production innovations. These advancements promise to boost efficiency and accuracy in casting processes while addressing the growing demand for lasting methods. As industries progress, the adoption of ingenious methods will likely redefine conventional spreading approaches and add to an extra eco responsible strategy.

Additive Manufacturing Assimilation

As markets look for cutting-edge services to boost manufacturing efficiency and decrease waste, the assimilation of additive manufacturing right into Metal Casting procedures becomes a additional reading transformative trend. This synergy permits the creation of complicated geometries that traditional techniques struggle to accomplish. By using 3D printing strategies, producers can generate mold and mildews and cores with detailed layouts, substantially lowering lead times and material consumption. In addition, additive manufacturing helps with fast prototyping, making it possible for quicker versions and changes in layout. This development not only improves manufacturing yet likewise encourages personalization, dealing with details customer demands. As this assimilation remains to evolve, it holds the potential to redefine Metal Casting applications, providing improved accuracy, lowered prices, and an extra lasting strategy to manufacturing in various industries.

Smart Manufacturing Technologies

Accepting clever manufacturing technologies marks a substantial shift in the future of Metal Casting applications. These improvements integrate automation, data analytics, and the Web of Points (IoT), boosting manufacturing effectiveness and quality assurance. By making use of sensing units and real-time surveillance, suppliers can enhance processes, decrease waste, and predict tools failings prior to they occur. Additionally, clever technologies make it possible for better modification of spreadings, permitting more complex layouts and faster turnaround times. The adoption of expert system in quality guarantee even more enhances defect detection, making sure higher item standards. As these modern technologies develop, they will not just improve operations however also foster innovation in Metal Casting, placing companies to meet the needs of a swiftly transforming industrial landscape.

Sustainable Casting Practices

Although typical Metal Casting methods have long been integral to production, an expanding emphasis on sustainability is improving practices within the sector. Modern foundries are increasingly taking on environment-friendly materials and procedures, such as utilizing recycled steels, which substantially lowers the environmental influence. Furthermore, innovations in modern technology enable a lot more efficient power use, minimizing waste and emissions during production. The consolidation of additive manufacturing methods better enhances sustainability by minimizing material waste and allowing for intricate layouts that were previously unachievable. In addition, industry stakeholders are prioritizing life process assessments to assess the ecological effect of Metal Casting. As the need for greener services escalates, lasting spreading methods are positioned to end up being a standard in Metal Casting, promoting an extra accountable and innovative production landscape.

Often Asked Questions

What Products Are Typically Utilized in Metal Casting?

Usual products used in Metal Casting include light weight aluminum, iron, steel, magnesium, and bronze. Each product uses distinctive residential properties, making them suitable for different applications, from automobile elements to intricate artistic layouts in manufacturing procedures.

Exactly How Does Metal Casting Contrast to Machining Processes?

Metal Casting normally offers better style flexibility and can produce complicated shapes much more effectively than machining. Machining provides greater accuracy and finer surface finishes, making each procedure ideal for different applications in manufacturing.

What Are the Typical Expenses Related To Metal Casting?

Typical expenses related to Metal Casting vary based upon aspects like intricacy, quantity, and product. First setup can be high, however huge production runs considerably minimize per-unit expenses, making it financially practical for numerous applications.

For how long Does the Metal Casting Process Take?

The Metal Casting process typically takes anywhere from a couple of hours to numerous weeks, depending upon aspects such as the complexity of the style, the product utilized, and the dimension of the cast things.

What Safety Procedures Are Required in Metal Casting Facilities?

Metal Casting facilities need precaution such as proper air flow, safety gear, emergency equipment, and regular training. In addition, keeping devices and sticking to safety procedures assures a safer working environment for all employees entailed in the process.

Metal Casting involves numerous vital methods, including sand spreading, investment casting, and die casting, each customized to specific applications and products. Inevitably, the clinical area makes use of specialized castings for surgical tools and implants, showcasing the adaptability of Metal Casting across varied applications. As advancements in innovation continue to improve click reference the production landscape, advancements in Metal Casting are emerging to improve efficiency, accuracy, and sustainability. As industries look for innovative solutions to enhance production performance and decrease waste, the integration of additive manufacturing right into Metal Casting procedures arises as a transformative pattern. Embracing clever manufacturing modern technologies notes a considerable shift in the future of Metal Casting applications.